THERMOFORMING

HOW DOES IT WORK?

Thermoforming is a technique that consists in taking a thermoplastic sheet and placing it on a frame in order to heat it to soften it prior to molding The resulting parts can meet the most demanding requirements and retain the properties of the chosen material. At DX Plastiques, we use one of three thermoforming processes depending on the part to be produced:

THE STEPS OF THERMOFORMING

Heating of plastic sheet in oven

Removal of plastic sheet from oven

Molding and shaping of part

Cooling of part

Demolding

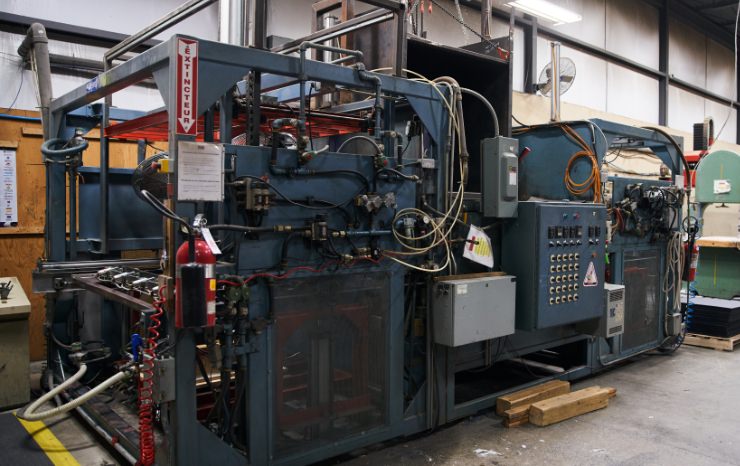

OUR THERMOFORMING EQUIPMENT

Our thermoforming technology allows us to mold plastic sheets measuring 64 inches long by 48 inches wide, for manufacturing parts up to 24 inches high and from 1/32 to ½ inch thick.

We use the following equipment:

- Hydraulic system that can be operated manually or automatically

- Digitally controlled ceramic-element furnace

- Twin-deck oven

- Dual temperature control by section

Are you ready to work on

your thermoforming project with our team?