Experts

thermoforming

Share your project with us! +

Experts

thermoforming

Share your project with us! +

THERMOFORMING

EXPERTS

SINCE 1992

DX Plastiques

Thermoforming is the art of using the properties of plastic under heat to warp it without breaking and create parts of impressive precision and quality. Discover the advantages of thermoforming now.

Our thermoforming services

For professional support, from design to delivery, consider our complete set of services.

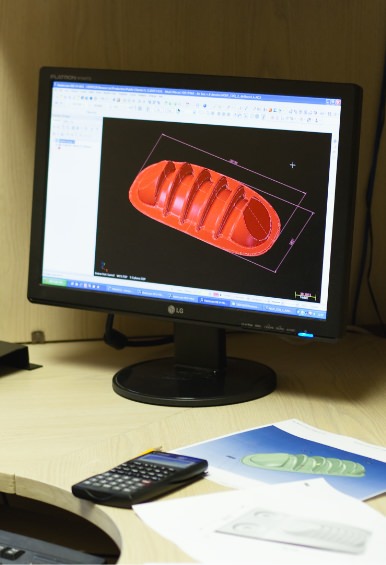

DESIGN

SUPPORT

MOLD

MAKING

THERMOFORMING

5-AXIS

MACHINING

ASSEMBLY

STORAGE

DX Plastiques, state-of-the-art expertise in thermoforming of your plastic parts. Our team will guide you all the way to the best plastic heat molding process.

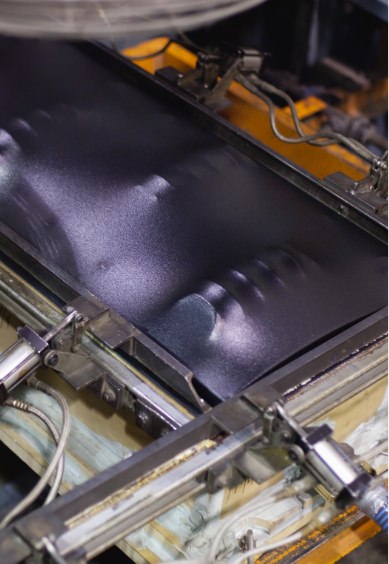

THERMOFORMING

Vacuum

The vacuum thermoforming process, also known as the vacuum method, is the most widespread technique in the plastic molding industry.

THERMOFORMING

Pressure

Pressure thermoforming uses the same method as vacuum molding, but with an additional pressure step.

THERMOFORMING

Compression

Compression thermoforming consists of using a male and a female mold and exerting substantial pressure on them.

OUR THERMOFORMING

expertise

30

number of years experience

4.0

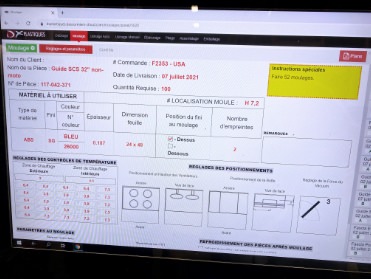

our state-of-the-art factory

WHY TRUST YOUR THERMOFORMING PROJECTS TO DX PLASTICS?

DX Plastiques

The Various Possibilities and Advantages of Thermoforming

With thermoforming, plastic molding opportunities are almost unlimited. Thermoformed parts have undeniable advantages: resistance, lightness, transparency, translucency or opacity, colour. Several texture and colour finishes are available. Finally, machining can complete the production of your thermoformed parts.

Moreover, DX Plastiques offers you even more in the manufacture of parts whose superior quality and cost control will meet your expectations.